Checking ADA Knee Clearance with the ADA Inspection Tool Kit

The ADA Inspection Tool Kit will save you Time and Money. It was designed for the busy ADA Compliance Professional. Get yours today.

100% Satisfaction Guarantee

or your money back

National Shipping

Support National Shipping

Free shipping

on selected products

What if my business is tax exempt?

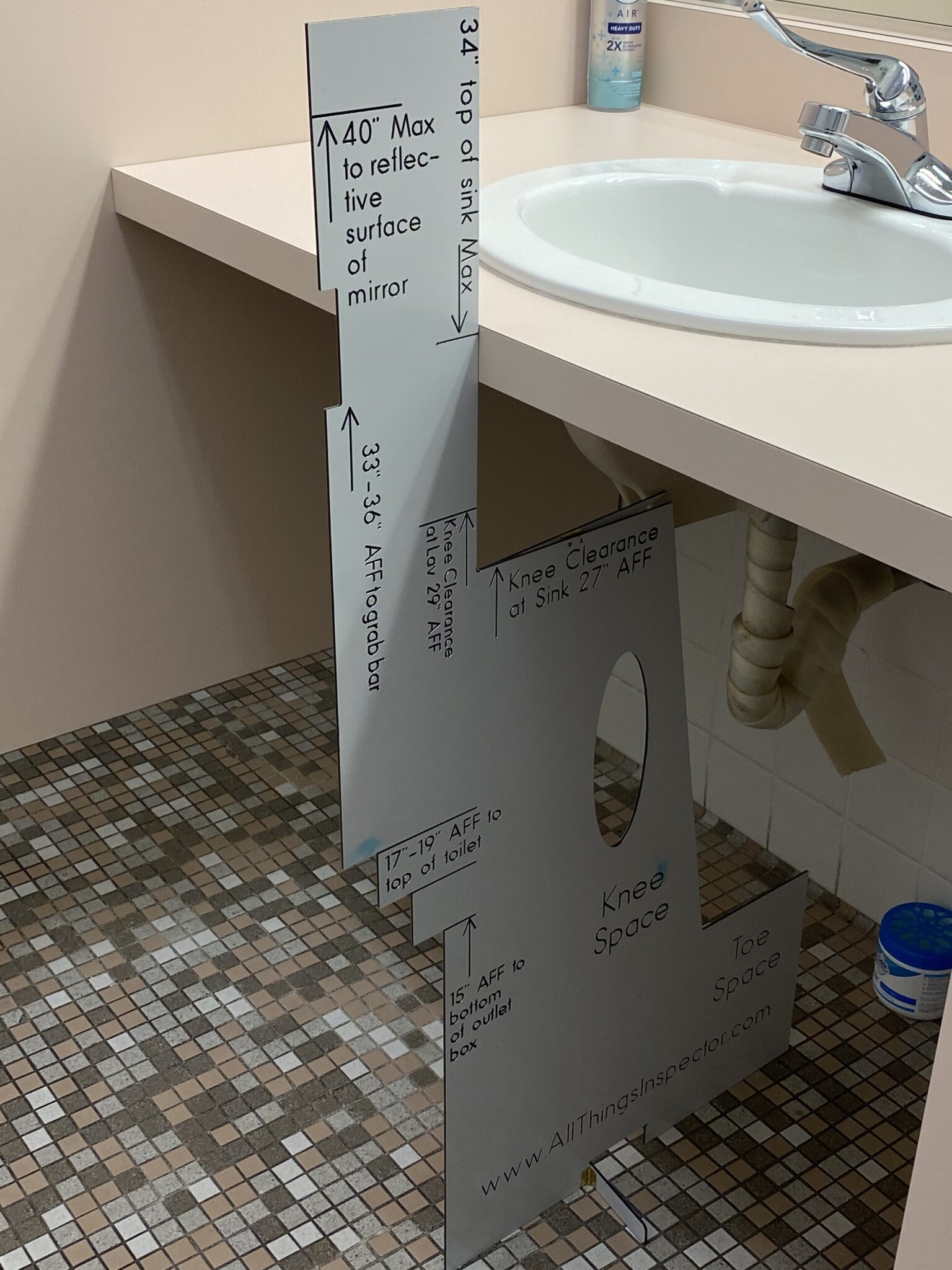

At All Things Inspector, we believe in helping you create spaces that are inclusive, accessible, and welcoming to everyone. Our commitment to accessibility is exemplified in our comprehensive range of products designed to help you meet and exceed ADA (Americans with Disabilities Act) standards. In particular, our ADA Knee Clearance template stand out as a testament to our dedication to helping ADA professionals save Time & Money while doing ADA accessibility surveys.

Imagine a world where every public space is thoughtfully designed to accommodate individuals with diverse needs, ensuring equal access and convenience. Our ADA Knee Clearance products are a pivotal component of this vision. Whether you’re an architect, designer, business owner, or facility manager, our collection offers innovative solutions that help you confirm facilities meet ADA compliance.

What is ADA Knee Clearance, and Why Does It Matter?

ADA Knee Clearance refers to the ADA knee space beneath tables, counters, and other surfaces, ensuring that individuals using wheelchairs or other mobility aids can comfortably approach and utilize these spaces. It’s not just about meeting regulatory requirements; it’s about fostering inclusivity and enhancing the overall experience for everyone.

Most popular product categories

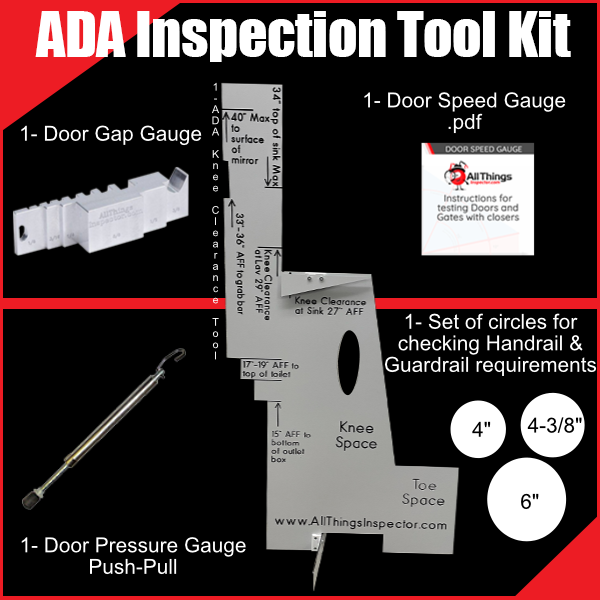

We have inspection tool kits for making your home and building inspections more efficient, saving you time and money. We carry specialty tools for fire door inspections, door pressure gauges, door gap gauges, ADA knee and toe clearance templates. We have a custom line of ADA site survey equipment to quickly check for ADA knee clearance and ADA compliance.

Door Pressure Gauge

Push Pull Gauge

Door Gap Gauge

Inspection Tool Kit

Funny Coffee Mug | Inspector | Mom | Gift

Instant Access Until You Pass

If you are serious about becoming a Commercial Building Inspector you will want to purchase one of our Inspector Online Practice Exams and visit our page about ICC Exam Preparation to learn a few pointers that may help you along the way. All Practice Exams and Study Material have been written and reviewed by a team of Certified Building Inspectors to help you improve your chances of passing your certification exam.

Featured

Best Seller

We have the best-in-class fire door inspection tool for measuring fire door gaps. We have created an extensive NFPA 80 fire door inspection checklist to help assist you with your fire door inspections.

Why Choose

All Things Inspector

If you’re looking for specialty tools for fire door inspections, door pressure gauges, door gap gauges, or ADA knee and toe clearance templates, we’re here to help.

As you prepare for your ICC exam, and our online mentoring sessions are a great way to get started. Our experts will walk you through the process step-by-step and answer any questions you have along the way.

We have ADA Compliance Inspection Tools That Make You More Efficient

Professional Services

Our mission is to keep our pricing simple with free shipping on qualified products.

Learn exactly what ADA Compliance is.

Our ADA inspection tools help you save time and money doing on-site ADA surveys.

The People Behind All Things Inspector and Bailey

FAQ

FAQ

Frequently Asked Questions

When it comes to fire door, ADA Compliance, door gap gauge there is no shortage of information. The most frequently asked questions has been answered by our team and we’ve provided you with some other relevant questions that often come up!

We have all the tools you need including door push pull force gauges in stock to check your door for ADA compliance.

We have the best tools to help you with your annual fire door inspection as well as we have put together a fire door inspection checklist that you can use as a guide.

Our ADA inspection tools help you save time and money doing on-site ADA surveys.

Free 25 Question PDF Commercial Building Inspector B2 Practice Exam

GET INSTANT FREE ACCESS to the 2015 International Building Code (25) Question PDF Practice Exam.

ICC Study Guide | 2015 Commercial Building Inspector PDF

Instant access when you purchase our proven ICC Study Guide PDF’s and use them to rocket you into passing your Commercial Building Inspector Exam.

Instructions For Testing Doors and Gates with Closers

Instructions For Testing Doors and Gates with Closers